Application methods and precautions of wet type peanut peeling machine

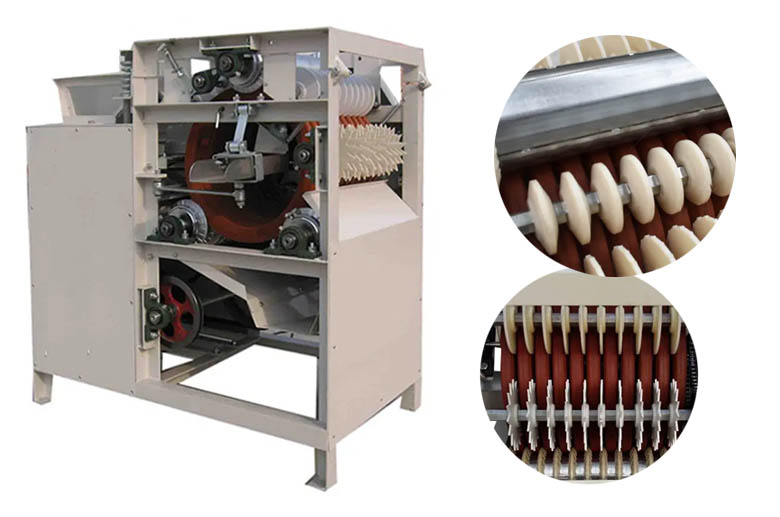

Wet type peanut peeling machine is a professional equipment for wet peeling of peanuts. During use, the soaked peanuts are poured into a hopper, the raw materials enter a rotating rubber wheel fixed by three power rollers through vibration, and the peeling effect is achieved through a manual twisting wheel under the action of an inducing strip and a feeding wheel; then the discharging wheel presses the peeled peanuts into a hopper and discharges them from the hopper, and the peel is thrown out through a peeling wheel.

The correct use methods of wet type peanut peeling machine is as follows:

1, The machine should be installed on a flat, hard ground, and have water supply and drainage facilities. 2. Check whether the bolts, motors and fasteners of the equipment are loose. 3. Turn on the power supply for trial operation to check whether the motor is running in the right direction. 4. All lubricating parts shall be lubricated, and the specified label lubricating oil shall be coated. 5. After all the above conditions are confirmed, the power supply can be turned on for normal use.

Only when the peanut wet peeling machine is used correctly and operated according to the operating rules can the machine be used safely and efficiently. Besides the correct use methods of peanut peeler machine, the following precautions should also be paid attention to when using the machine:

First, before use, first check whether the fasteners are tightened, whether the rotating parts are flexible, whether there is lubricating oil in each bearing and whether it is placed smoothly. In order to ensure the safety of operators, it is also necessary to take grounding protection for the motor shell (connect the motor shell with the grounding body reliably with wires).

Second, apply manpower to turn the peanut wet peeling machine several times before electrifying. If there is a crash, find out the reason and electrify it again.

Third, the appropriate screen should be selected according to the size of peanut kernel.

Fourth, after power-on, we should start trial operation and pay attention to whether the rotor turns correctly. After the motor is started, the rotation direction of the rotor should be consistent with the direction marked on the machine. Idle for a few minutes, observe whether there is any abnormal noise, and then put peanuts into the hopper quantitatively, evenly and continuously after normal and stable operation.

Fifth, when peeling, peanut input should be even and appropriate, and iron filings, stones and other sundries are not allowed to be mixed in, in case of breaking peanuts or causing mechanical accidents. Only when peanuts cover the sieve surface fully can the outlet switch be turned on.

Fifth, before storing the machine, clean the dust, dirt, grains and other sundries on the outside of the machine, then clean the bearings in various parts with diesel oil, dry them, coat them with grease, cover the machine and store them in a dry warehouse. The belt should be removed and hung on the indoor wall that is not exposed to the sun.

The above are the correct methods and precautions when using the wet type peanut peeler machine. Knowing these can not only help us to use the peanut peeler better, but also prolong the service life of the machine, so we should pay attention to it.