Wet Type Peanut Peeling Machine

Design and Advantages: Wet Type Peanut Peeling Machine

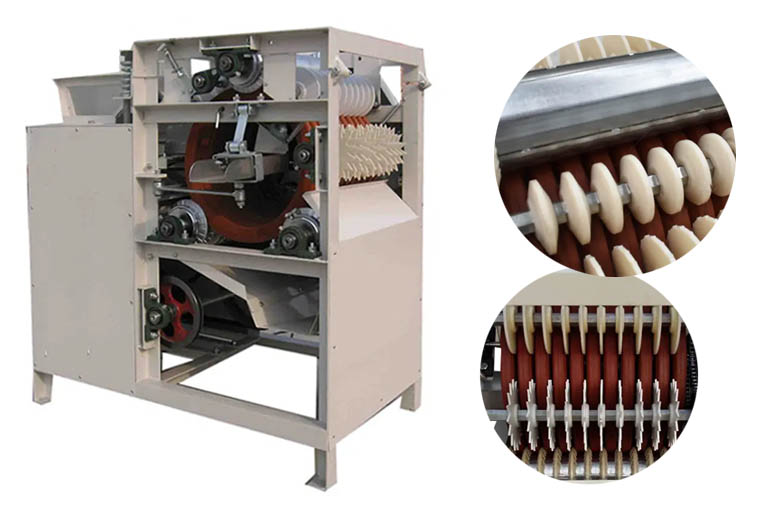

Diverging from the dry type peeling method that involves roasted peanuts, the wet type peanut peeling machine employs a unique technique. Peanuts are immersed in hot water for a brief period before the peeling process commences. The machine features high-standard pure soft rubber wheels that gently and efficiently remove the skin, akin to the delicate touch of human hands. Notably, the peeling process preserves the protein and integrity of the peanut and other nuts. This method is particularly well-suited for the removal of peanut, soybean and almond skins, making it the go-to choice for enhancing product quality.

The wet type peanut peeling machine boasts an intricate yet efficient design. With a foundation in the hand peeling principle and incorporating special peeling components, it achieves remarkable peeling rates and high whole kernel retention. The machine is characterized by its compact construction, non-polluting operation, low power consumption, and simultaneous peeling and skin separation. Whether utilized independently or integrated into a production line, it demonstrates exceptional capabilities.

Technical parameters:

| KMST-8 | KMST-11 |

| Power:0.75kw ;Voltage:380V Peeling Rate:96% Broken Rate: 6% Size:1100*660*1050 Production Capacity:150-160kg/h | Power:0.75kwX2 Peeling Rate:96% Broken Rate: 6% Dimensions: 1100*760*1050mm Production Capacity:200-220kg/h |

Application for Peanut Peeling Machine

The applications of the wet type peanut peeling machine extend across a range of peanut-based products. It is the quintessential equipment for the removal of red skin from peanuts and almonds. The processed output from this machine serves as a foundation for fried peanuts, peanut milk, almond peanut protein powder, and almond juice. Its adaptability makes it indispensable in the preliminary peeling stages of fried peanuts, spiced peanuts, eight-treasure congee, pickled peanuts, and beyond.

Operation Tips for Peanut Peeling Machine

To ensure the machine’s peak performance, adhering to certain operational tips is crucial. The proper screening of peanuts to achieve uniform size is of paramount importance. This contributes to an efficient and consistent peeling process. Additionally, adjusting the peeling rollers’ spacing according to the peanuts’ size enhances the overall efficiency. A general guideline suggests maintaining a roller space 2-3 mm smaller than the peanut’s diameter.

KMEC Peanut Peeling Machine Manufacturer

Our company is proud to offer a top-of-the-line wet peanut peeling machine that is both reliable and high-quality. With years of industry experience and a focus on peanut machinery, we have built a reputation for excellence. Our machines, which include peanut peeling, roasting, and butter machines, come with a one-year warranty, demonstrating our commitment to customer satisfaction. We prioritize quality and efficiency in all of our products, and our peanut peeling machine is no exception. By utilizing innovative technology, we have created a machine that can improve the quality, flavor, and efficiency of both commercial and homemade peanut products. Trust in our expertise and invest in our peanut peeling machine for optimal results.